To watch the video on this subject go to ‘Stair Components and Terminology’

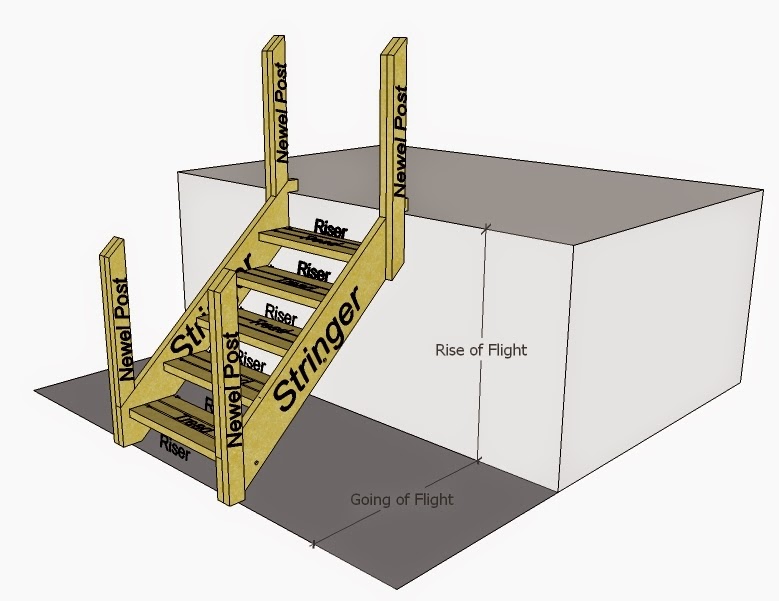

Rise Of Flight

The rise of flight is the vertical distance between the finished floor levels (F.F.L) or landings.

Going of Flight

This is the horizontal distance from the face of the first Riser to the face of the last Riser.

String or Stringer

Designed to carry the load of the stairs, there can be 1, 2 or even 3 for wide stairs. They normally form the side of the stairs however they can also be placed underneath.

Tread

The part that you step on.

Riser

The Riser or Riserboard closes the gap between the Treads. Normally omitted in External or Industrial stairs.

Newel Post

This is the upright post attached to the Stringer which supports the Handrail.

Handrail

Runs Parallel to the Stringer a minimum of 865mm vertically from the margin line. It provides support for the users.

Balusters

The vertical members that fill in the space between the Handrail and the Stringer.

Balustrade

Rise of Step

This is the distance from the top pf one Tread to the top of the next.

Going of Step

This is the distance from the front on one tread to the front of the next.

Margin

This is the distance from the edge of the stringer to the point of the treads.

Tie Rods

Used to tie the stringers together so they don't separate over time. Spaced every 1350mm along the length of the Stringer.